Location: Belgium-Netherlands border

Sector: Fresh Produce / Cold Storage

Client: Fruit Services Collective (FSC)

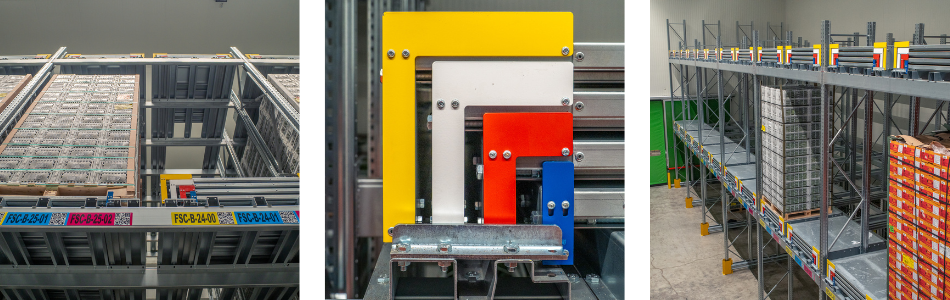

Solution: Customised pushback racking system

Key benefit: 550% increase in storage capacity

Just a stone's throw away from the Belgian-Dutch border near Meer sits the new state-of-the-art warehouse of Fruit Services Collective (FSC). Established by international fruit supplier Special Fruit, FSC specialises in the ripening and distribution of fruit, primarily avocados - and now serves a growing client base beyond its parent company.

From ripening to packaging and outbound logistics, FSC aims to manage the entire supply chain under one roof, all while upholding the highest standards of freshness and efficiency.

Smart ripening for smart logistics

At the heart of FSC's operations is an innovative soft-ripening process, developed to produce "ready-to-eat" fruit. Unlike conventional air-freight ripening, this method allows avocados to be harvested in an immature state, shipped under stable conditions, and then ripened locally using AI-driven, sensor-based systems.

This approach extends shelf life, improves quality, and ensures the fruit reaches supermarket shelves in optimal conditions, all while minimising energy consumption and waste.

An empty warehouse, a blank canvas

When FSC acquired an existing industrial unit in early 2023, it was a clean slate. Head of FSC, Willem-Jan Kwisthout, was tasked with designing the warehouse layout from scratch. This challenge demanded not only a functional flow between ripening zones and cold stores but also close attention to temperature control and energy efficiency.

“In this industry, every pallet space counts,” explains Willem-Jan. “We needed a storage solution that maximised capacity while keeping our operations fast and flexible.”

Searching for the right solution

Initially, pallets of ripened fruit were stored directly on the floor across six cold stores, accommodating roughly 80 pallets per cell. This was never meant to be permanent.

Several options were explored during the design phase:

- Single-depth racking offered fast access but too little capacity.

- Mobile racking provided compact storage but limited immediate access to pallets.

- Drive-in and flow racks posed challenges with FSC’s varied pallet sizes and product heights.

- Electric pallet shuttle systems, while promising, didn’t justify the cost at this stage.

With energy prices rising and volumes growing, it became clear that a high-density solution with straightforward access was essential.

Custom-engineered pushback racking

Drawing on Willem-Jan’s previous experience, FSC opted for a flat-deck pushback racking system using trolley-based lanes. Unlike traditional sloped pushback systems, this design uses four stackable trolleys that nest smoothly within the rack - avoiding the risk of product instability due to pallet height.

The system’s design enables selective access, smooth pallet movement, and hygienic storage - all crucial for FSC’s operational and food safety requirements.

Why did they pick Dexion?

FSC invited several storage suppliers to pitch. Ultimately, Dexion was awarded the project due to its consultative approach and flexibility in adapting the solution to FSC’s needs.

“In collaboration with Dexion, we rolled out the racking in phases,” says Willem-Jan. “They even pre-installed floor stops in each cell, a simple but smart idea that saved us time down the line.”

Adapting to the new system took some getting used to, especially for reach truck drivers handling top-tier pallets. But the benefits were immediate and measurable.

Storage capacity up by 550%

Where one cold store once held just 80 pallets, the new solution now fits up to 440 pallets per cell, an increase of over 550%. Each rack lane extends four pallets deep, maximising the use of the warehouse's height.

This allowed FSC to scale output rapidly without increasing staff numbers, a critical factor in a labour-intensive sector.

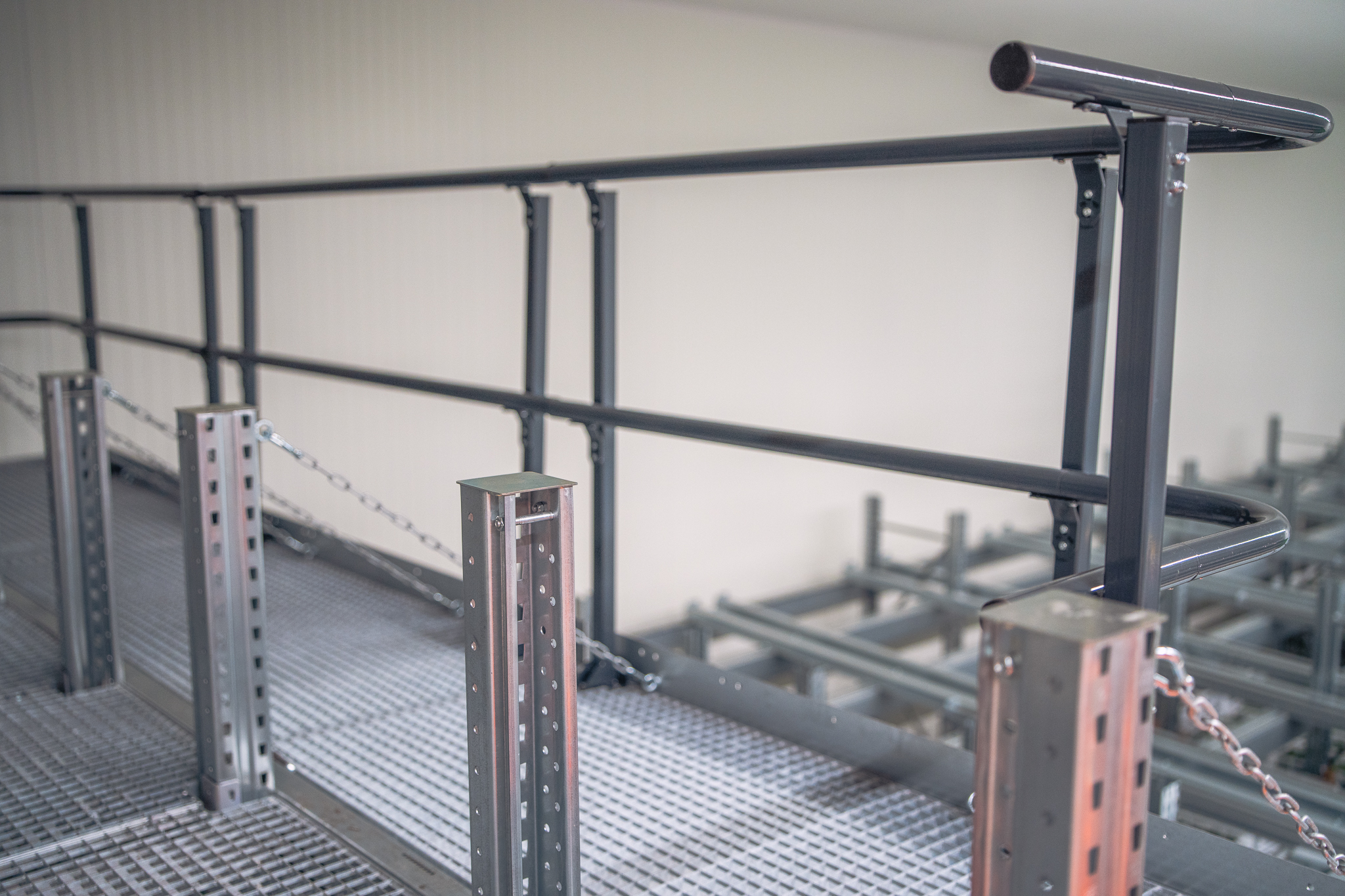

Smart thinking at height

One final challenge remained: how to maximise vertical space while maintaining access to the cooling units installed 7 metres up the wall.

The solution? A hinged racking section was developed in collaboration with Dexion and the refrigeration team. By temporarily removing select pallets and folding away the rack section, maintenance teams can reach the units without dismantling the structure.

A partnership built on innovation

For both FSC and Dexion, the project was a perfect match.

“These types of greenfield projects are the most rewarding,”says Dirk Geets, Consultant at Dexion. “Willem-Jan and his team knew what they wanted but were open to ideas. Together, we delivered a solution that’s scalable, efficient and ready for the future.”